Top features of cleaning and disinfection appliances

What makes a good cleaning and disinfection machine

The goals of our innovative technology and functionality are twofold: hygiene safety for patients and residents, and workplace safety for care staff. A MEIKO cleaning and disinfection appliance is a safe bet for both. The following features and functions make the cleaning process especially hygienic.

Infrared control system and/or foot switch

These options enable you to open the doors of the appliance without touching it. Simply use the foot switch or move your hand in front of the sensor.

Benefits:

- Contactless door opening

- Prevents potential contamination via hands

Optional on TopLine and TOPIC

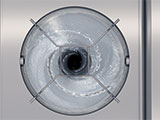

Telescopic rotary jet

The wash chamber features an extendable telescopic rotary jet and wash nozzles around 360° for efficient care utensil cleaning—down to every last nook and cranny.

Benefits:

- Targets cleaning on the interior of different shapes of bedpan

- Highly efficient at washing away microbes

- The interplay between mechanical washing, temperature, and detergents (optional) is even effective (confirmed by expert opinion) against Clostridium difficile spores (now known as Clostridioides difficile)

Standard on TopLine (PowerClean)

Temperature control

Each programme run is controlled according to the set A0 value and documented. Two sensors cross check one another, ensuring it reaches the required temperatures and maintains it for the set length of time.

Benefits:

- The highest level of hygiene safety

- Validates disinfection performance and the cleaning process

Standard on TopLine and TOPIC (ThermoControl)

Drying and cooling

Dry&Cool: the clue is in the name! Care utensils are dried and cooled before they are unloaded. The air used for this process is filtered beforehand using a patented process.

Benefits:

- Sterile air thanks to the HEPA filter

- No risk of recontamination

- Items can be used again for patients immediately

Standard on TopLine (Dry&Cool), optional on TOPIC

System disinfection

The hot steam is fed through all water pipes into the wash chamber.

Benefits:

- Thermal disinfection of all elements in the water system (pipes, nozzles, water tank) over the programme run

- No recontamination of the system

Standard on TopLine and TOPIC (T.A.D. or Total Auto Disinfection)

SteamStop

After the wash programme has finished, steam is removed from the wash chamber so there is none of it when you open the door! Instead of releasing the excess steam into the room, the machine channels it straight into the drain using a separate pipe.

Benefits:

- No additional heat in the utility room

- No risk of pathogens escaping into the room, i.e., excellent workplace and hygiene safety

Standard on TopLine and TOPIC (SteamStop)

Suction lance coding system

Blue to blue, grey to grey: the unique colour coding on our suction lances and supply canisters keeps it clear which is detergent and which is rinse aid. There is no way to mix them up.

Benefits:

- Process reliability

- User safety

Standard on TopLine and TOPIC (ChemCode)

Dosing system for detergent and rinse aid

No need to worry about dosing water softener with rinse aid or detergent (optional). It is all monitored and controlled by sensors.

Benefits:

- Optimum dosing of chemical agents

- Automation provides hygiene safety

Standard on TopLine and TOPIC (CaStop)

Adjustable A0 value

You choose the programme—the cleaning and disinfection appliance can be run with any of the following A0 values at any time: A0 60, A0 600, or A0 3,000. Select the value according to your needs, such as potential outbreaks or on isolation wards.

Benefits:

- Hygiene safety for patients

Standard on TopLine, optional on TOPIC (in combination with MEIKO Dry&Cool)

Tailored holder systems

There are often many types of washware in a single facility. Custom builds and universal holders by MEIKO ensure that all shapes of care utensil get the optimum clean.

Benefits:

- Perfect results on every cleaning cycle thanks to holders that are tailored to individual customer needs

Optional on TopLine and TOPIC

Stainless steel surfaces

Seamless connections and sealed surfaces that perfectly connect the individual components make our brand distinct. Everything is made from stainless steel.

Benefits:

- Optimises hygienically safe workspace for results that fulfil all customer and statutory requirements

- Stainless steel surfaces have a bacteriostatic effect and are easy to clean and disinfect

Standard on TopLine and TOPIC

Slop sink unit with integrated flushing

Two self-cleaning water nozzles in the slop sink unit produce a powerful spiral flush for a whirl effect. This completely washes away dirt and residues.

Benefits:

- More hygiene from every angle

- The seamless slop sink rim contributes significantly here

Optional on TopLine and TOPIC

At the end of the washing operation the M-iQ cleans itself using the existing tank water. Only the parts which are blue have to be manually cleaned.

The new slop sink unit saves over 50% on water, improves safety and is incredibly convenient to service, making it a must-have for every conscientious ward.

M-Commander InVision data analysis software

This features documents all relevant load data from appliances so you can view, read, or transfer it to your PC easily at any time.

Benefits:

- Monitor hygiene, logistics and service management

- Provides comprehensive documentation of appliance status and the quality of cleaning processes

- In the event of a malfunction, identifying errors is easier, and the data facilitates onsite service

Optional on TopLine and TOPIC